Key Takeaways

- Operational efficiency in manufacturing means refining processes to reduce waste, costs, and time without compromising on quality or output.

- With technology, such as AI, IoT, smart factories, and data, manufacturers can lower expenses, boost quality, and increase transparency throughout the supply chain and production processes.

- Operational efficiency and technology can help bridge the talent gap, improving employee productivity and engagement.

The manufacturing industry has experienced rapid growth. However, conducting business has also become increasingly complex. Supply chain disruptions (52%), rising business costs (35%), and high interest rates (26%) are all contributing to disruption for manufacturers, according to our recent survey of mid-level manufacturers.

- Download the report to learn more about the state of manufacturing.

The truth is high-performing manufacturers are prioritizing productivity and profitability to increase operational efficiency. Here’s how.

Operational Efficiency in Manufacturing

You can boost their profits and improve efficiency in various ways, including lean manufacturing processes, technology, data, AI, and more.

Technology

A strategic digital approach is paramount. Reliance on legacy systems creates obstacles. In fact, over 60% of mid-level manufacturers say updating their existing technology is one of the largest growth opportunities.

Smart Factory Technology

The Industrial IoT (IIoT) enables you to make informed, strategic decisions based on real-time data. Predictive maintenance and predictive resolution leverage data analysis to identify anomalies in equipment performance and provide insights into issues. This interconnection of devices within an existing internet structure supports cost reduction, higher efficiency, improved safety, and product innovation.

And while there’s much opportunity, only about 7% of manufacturers say they have effectively implemented digital factory operations.

Operational Technology

Careful planning is crucial to ensure successful technology implementation. Otherwise, you risk giving up the very efficiency you’re hoping to achieve.

The key is choosing technology that actually targets process inefficiencies and folds into your bigger picture.

The right business solutions can increase operational efficiency by helping manufacturers better understand:

- Expense forecasting. Technology gives visibility into the root causes of expenses to help manufacturers develop a more strategic approach to a better bottom line.

- Production costs. Technology applications can also monitor production costs in real-time, from raw materials procurement to delivery. For example, manufacturers can discern accurate margins with better insight into inventory costs.

- Inventory tracking. Manufacturers can use technology to track inventory levels and optimize the ordering process. The result is increased visibility, reduced inventory holding costs, lower volumes of stock-outs, and more timely customer deliveries.

Black Clover was operating around data chaos that limited its capacity to grow. With a sophisticated data warehouse and a custom reporting solution, they gained game-changing visibility into their operations. Read the case study to learn more.

Inventory Efficiency

Improving inventory efficiency is a pervasive industry challenge.

Common challenges include:

- Incorrect or poorly managed pick logic

- Warehouse layout

- Incorrect quantities

- Limited inventory visibility

- Inefficient inventory management processes

- Identifying misplaced materials

- Tracking waste and obsolete goods

Take for instance, SkinScript, a skincare products manufacturer and distributor. By implementing an advanced inventory and warehouse management system, coupled with their ERP, the company was able to triple their volume without needing to hire, add space, or upgrade their technology.

- Read more about how SkinScript achieved complete inventory management.

Data-Driven Decision-Making

Manufacturers can lower costs, predict future impacts, and identify inefficiencies with real-time data.

Accurate, integrated data, ensures you can:

- Predict equipment failures to prevent production disruptions.

- Assess rising cost areas like employee turnover or raw material procurement.

- Forecast the future based on current inventory, market fluctuations, and past consumer behavior.

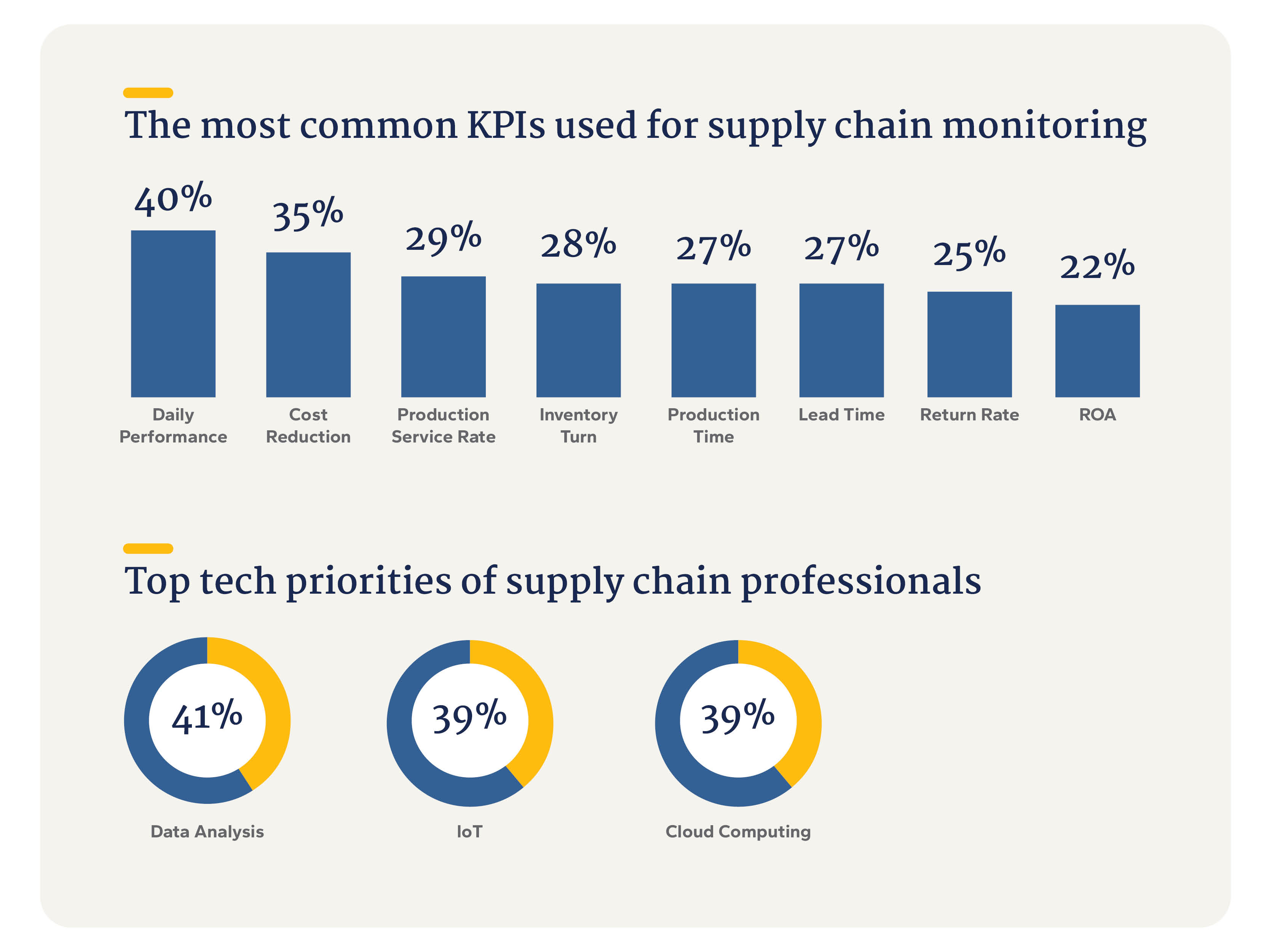

- Gain supply chain visibility. Almost half of mid-market manufacturers and distributors say they are making efforts to improve end-to-end supply chain visibility in recent months.

- Learn more about the critical role of supply chain visibility in 2025.

The Role of Automation in Supply Chain

Deploying automated inventory management systems and enhancing supply chain visibility contribute to a well-functioning supply network. Cloud-based IIoT and AI-led systems facilitate real-time goods tracking, improved supply chain collaboration, and seamless communication.

79% of companies with strong supply chains achieve significantly higher revenue growth.

Improved supply chain visibility equips you with the data you need to make smarter decisions today and into the future. It will help you pivot sooner when an issue arises and identify areas to proactively manage risk.

Artificial Intelligence

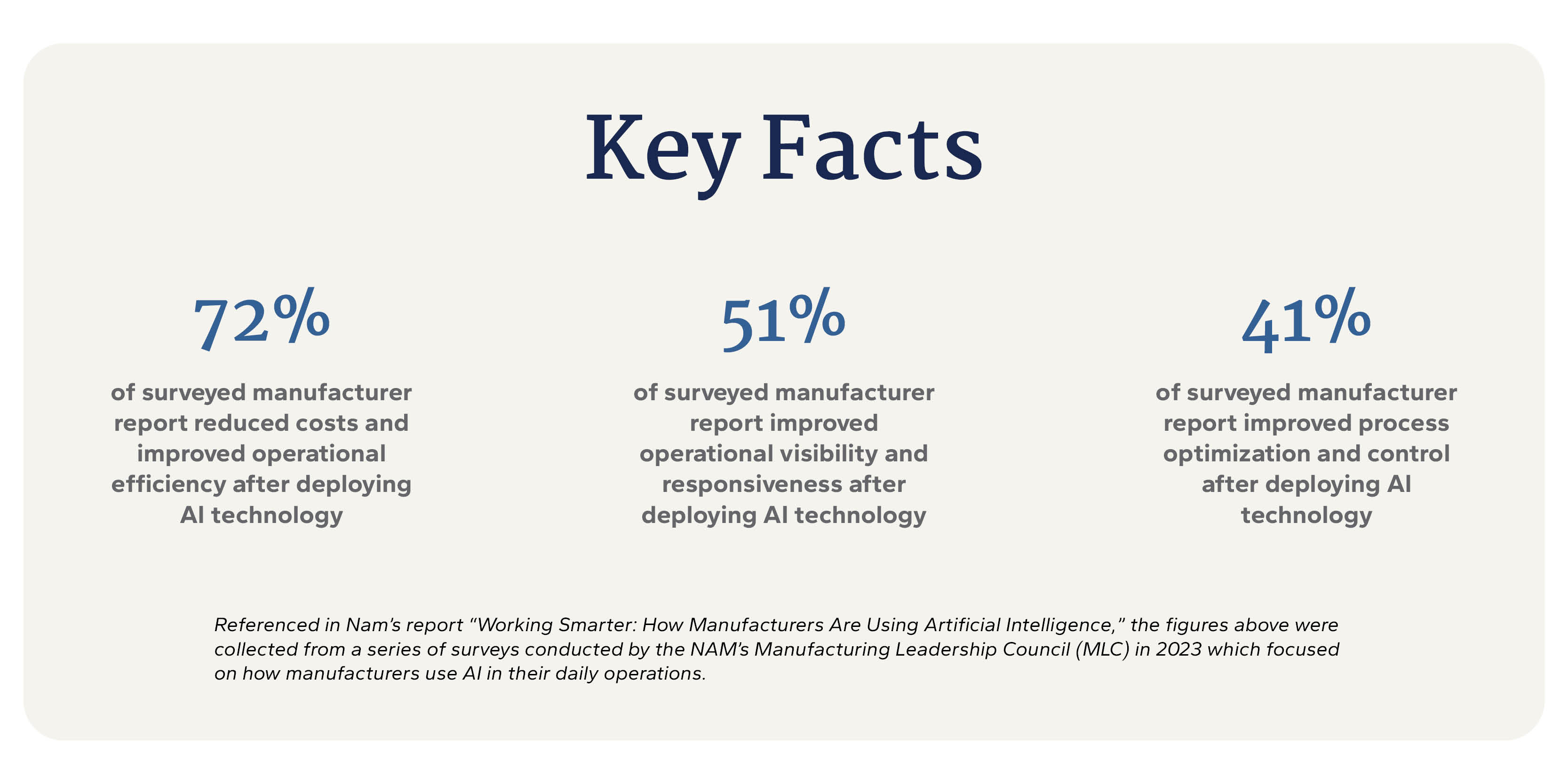

From an efficiency standpoint, manufacturers are using AI to streamline processes, enhance production quality, and improve overall efficiency.

Recent research found that more than half of manufacturers (57%) plan to include AI in their production operations within the next few years. And for good reason. Studies have shown that manufacturers reduced machine downtime by 30 to 50% when utilizing AI.

While launching an AI initiative may seem daunting, there are ways you can increase efficiency right now for little to no dollar investment.

- Educate yourself. Invest two to four hours a week learning about AI and how it can improve your business.

- Develop use cases. Identify where AI can bring value to your organization. We’ve seen companies achieve success using AI for predictive maintenance, demand forecasting, and supply chain optimization.

- Start with data. AI runs off data. If your data isn’t in order, your AI strategy will fall flat. Prioritize a robust data infrastructure that collects, stores, and makes data easily accessible by conducting a comprehensive data assessment.

- Learn more: How to Apply AI Strategically

Operational Efficiency and the Workforce

Effectively addressing the challenges of a tight labor market and workforce is a top industry pain point. In fact, by 2033 approximately four million manufacturing jobs will likely be needed, with 2.1 million expected to go unfilled.

To attract and retain employees, many manufacturers are turning to technology to lighten the workload. Automation and robotics can help bridge the talent gap and help drive optimal performance. Having advanced, competitive technology in key areas of your operations – including your factory floor – can not only make you more attractive to up-and-coming industry professionals but also more efficient.

Operational Efficiency is Critical for Prospering Tomorrow

Operational efficiency is not a one-time goal, but continuous. To achieve long-term success, optimize your technology and review operations to ensure they’re truly delivering value.

The result is more visibility, agility, and flexibility across your supply chain and production processes.

Make a habit of sustained success.

Manufacturing, Distribution, and Logistics

Rely on the trusted expertise of manufacturing advisors to help you build and execute your strategic vision.

Who We Are

Eide Bailly is a CPA and business advisory firm helping our clients grow, thrive, and embrace opportunities and innovation.

.jpg?h=560&iar=0&w=700)